2026 Top Uses of Stainless Steel Wire Mesh for Industrial Applications?

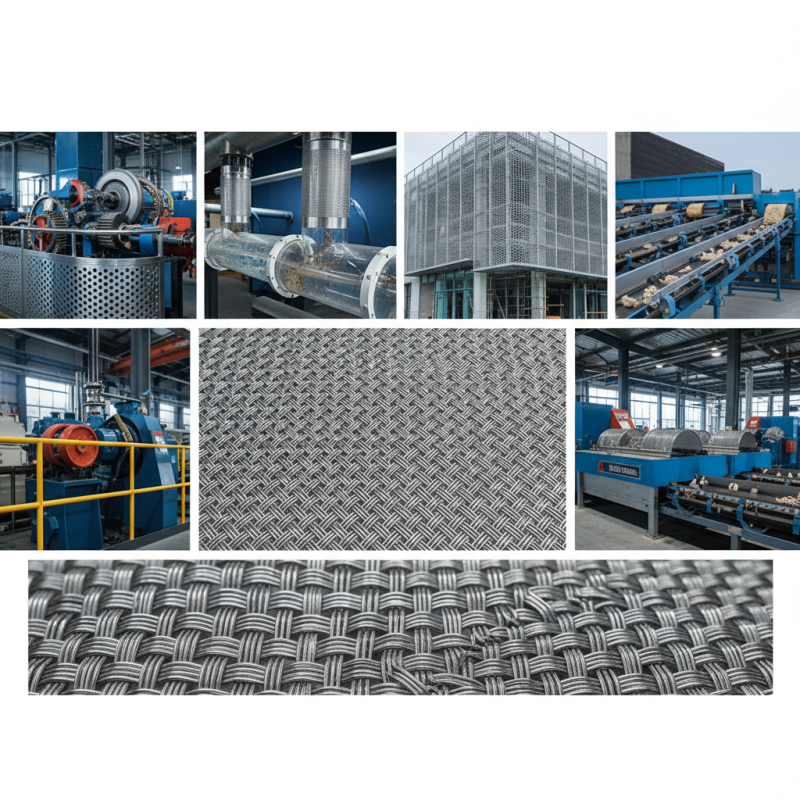

stainless steel wire mesh is a versatile material used across various industrial applications. Its durability and resistance to corrosion make it ideal for many environments. According to a recent market analysis by Smithers Pira, the stainless steel wire mesh market is expected to grow by 6.3% annually through 2026. This growth reflects increasing demand across sectors like construction, automotive, and food processing.

The unique properties of stainless steel wire mesh contribute to its widespread usage. For instance, it provides safety without compromising visibility. Many industries rely on it for filtration and support structures. It offers a practical solution for separating materials in recycling plants, protecting against material loss. Yet, challenges remain. Not all stainless steel wire meshes are made equally, and poor quality can lead to failures or safety hazards.

Consideration must be taken in selection and application to ensure optimal performance. Investing in high-quality stainless steel wire mesh can save resources in the long run. Understanding its strengths and weaknesses is key for industries to maximize benefits. With 2026 on the horizon, strategic use of stainless steel wire mesh will shape operational efficiency and innovation across various fields.

2026 Overview of Stainless Steel Wire Mesh in Industrial Settings

Stainless steel wire mesh is gaining prominence in various industrial settings in 2026. Its versatility makes it suitable for filtration, safety, and structural applications. Industries such as food processing, pharmaceuticals, and construction benefit from this material. For example, in food processing, it ensures hygiene and safety by preventing contamination.

When using stainless steel wire mesh, consider its mesh size. A finer mesh can trap smaller particles. This is crucial in applications like air filtration, where air quality matters. Think about durability too. Mesh exposed to harsh conditions needs to withstand corrosion and wear.

Tip: Always assess your specific needs before choosing a mesh type. Reflect on the environment where it will be used. Trial and error might lead to the best results. Adjustments may be necessary along the way. Using stainless steel wire mesh can present challenges but offers lasting benefits when properly implemented.

Key Industrial Applications of Stainless Steel Wire Mesh in 2026

Stainless steel wire mesh is increasingly crucial in various industrial applications for 2026. Its strength and durability make it ideal for demanding environments. Industries like food processing, pharmaceuticals, and mining heavily rely on it for filtration and protection.

In food processing, stainless steel wire mesh is used in equipment for filtering and sifting. It helps maintain hygiene standards. A report indicates that about 40% of food safety systems now utilize this mesh. It prevents contamination, ensuring product quality and safety.

In the mining sector, this mesh plays a key role in mineral processing. Studies show that its use enhances efficiency, leading to better resource recovery. However, some industrial users struggle with mesh corrosion in harsh environments. Regular maintenance is vital here.

Tips: Always check the grade of stainless steel wire mesh before purchasing. Selecting the right type can significantly impact your project’s success. Regular inspections can prevent unexpected failures.

Market Trends: Growth of Stainless Steel Wire Mesh Usage in Industries

The industrial landscape is evolving, and stainless steel wire mesh is at the forefront. Its durability and versatility are driving growth in various sectors. You can find it in construction, automotive, and food industries. With increasing awareness about hygiene and safety, stainless steel wire mesh is becoming a go-to choice. Its resistance to corrosion makes it ideal for harsh environments.

Tips: Consider the mesh's size. The right size ensures optimal performance in filtration processes. Always evaluate your specific application needs. Choosing the wrong mesh can lead to inefficiencies.

Market trends show a surge in demand for stainless steel wire mesh. Industries seek sustainable solutions. It contributes to a circular economy by being recyclable. However, the increasing demand may lead to resource shortages. This potential imbalance needs addressing.

Tips: Regular maintenance of stainless steel wire mesh can extend its lifespan. Invest in quality materials to reduce long-term costs. Remember, a small oversight can lead to significant issues down the line.

2026 Top Uses of Stainless Steel Wire Mesh for Industrial Applications

Performance Metrics: Benefits of Using Stainless Steel Wire Mesh in Industry

Stainless steel wire mesh has gained traction in various industrial applications. Its durability and strength make it ideal for demanding environments. This mesh can withstand extreme temperatures and is resistant to corrosion, enhancing its longevity. Industries rely on these features for filtration, sieving, and barrier purposes.

The performance metrics of stainless steel wire mesh highlight its strategic advantages. It allows for efficient airflow and liquid flow, which is critical in many processes. The versatility of the mesh enables it to be customized for different sizes and shapes. This adaptability can sometimes lead to oversights if specifications are not finely tuned.

However, not all aspects are flawless. Cost considerations arise when selecting the appropriate mesh. While it offers many benefits, the initial investment can be a barrier for some. Additionally, care must be taken to ensure proper installation to avoid potential failures. These factors require careful reflection when integrating stainless steel wire mesh into industrial applications.

2026 Top Uses of Stainless Steel Wire Mesh for Industrial Applications

| Application | Advantages | Performance Metrics | Industry |

|---|---|---|---|

| Filtration | Corrosion resistance, durability | High flow rate, effective particle retention | Chemical Processing |

| Safety Screens | Strength, visibility | Impact resistance, long lifespan | Construction |

| Cages and Enclosures | Customizable, strong | Load-bearing capacity, ease of installation | Food production |

| Filters | Resistance to heat and chemicals | Efficiency, filter life | Water Treatment |

| Architectural Features | Aesthetic appeal, rust resistance | Design flexibility, longevity | Architecture |

Future Innovations in Stainless Steel Wire Mesh Technology for 2026

Stainless steel wire mesh continues to evolve, offering fresh possibilities for industrial applications in 2026. Innovations aim to improve efficiency and sustainability. Enhanced durability makes stainless steel mesh more attractive for harsh environments. Anti-corrosion technology is being developed, which extends the lifespan of the mesh.

Manufacturers focus on customization. Designs can now meet exact specifications and performance requirements. This adaptability opens new opportunities in various sectors, from construction to food processing. Companies can choose different weave patterns and mesh sizes to suit their needs.

Tip: When selecting wire mesh, consider the specific environment it will face. Test various types to see which performs best under specific conditions.

Another exciting trend is the integration of smart technology. Sensors can be embedded within the mesh. They track performance in real time, providing crucial data for maintenance decisions. This can prevent costly downtime, but it still requires careful planning and investment.

Tip: Experiment with pilot projects before full implementation. This approach helps identify challenges early on. It’s a practical way to ensure that innovations are beneficial.