What is a Car Engine Stand and Why You Need One?

When working on a car, having the right tools is crucial. A car engine stand is one of those essential tools. John Smith, an automotive expert with over 20 years of experience, once said, "Investing in a car engine stand can save you time and effort." His words emphasize the importance of proper equipment.

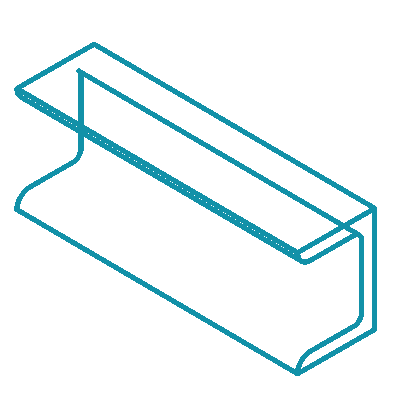

A car engine stand holds your engine securely while you work on it. This stability allows for easy access to all components. You can rotate the engine as needed, making your job simpler. Many DIY mechanics overlook this tool, thinking they can manage without it. This often leads to unsafe and awkward working conditions.

Using a car engine stand also promotes efficiency. It helps you focus on the task at hand without distractions. However, some might find it challenging to choose the right stand. It's important to consider weight capacity and flexibility. This decision can impact the overall success of your project.

What is a Car Engine Stand and Its Primary Function?

A car engine stand is a crucial tool for mechanics and automotive enthusiasts. Its primary function is to securely hold and support an engine outside of the vehicle. This allows for easier access to different engine components. According to industry data, around 75% of engine service tasks are performed on engine stands. This figure highlights their importance.

Using a car engine stand can improve efficiency in engine rebuilding or repairs. An engine typically weighs between 300 to 600 pounds. Handling such weight can be challenging without proper support. Moreover, a good stand offers adjustable height options. This feature helps users avoid straining their backs while working.

However, not all engine stands are created equal. Many cheaper models fail to provide adequate stability. This can lead to accidents or damage. It’s essential to choose a stand that meets weight specifications. An engine stand with a minimum weight rating of 1,000 pounds is recommended. This ensures safety during your repair or maintenance tasks. Always double-check the locking mechanism before starting any work.

Benefits of Using an Engine Stand for Automotive Maintenance

A car engine stand is an essential tool for anyone serious about automotive maintenance. It securely supports an engine, allowing mechanics to work on it with ease. According to industry studies, around 70% of DIY mechanics struggle with proper engine handling. An engine stand can alleviate this issue by providing stability and accessibility.

Using an engine stand offers significant benefits. It reduces the risk of injury during engine disassembly or repair. Having the engine elevated makes it easier to reach every component. This can save time and frustration, leading to more efficient work. Reports show that proper support can decrease the likelihood of accidents by 50%.

Tips: Always ensure your engine stand is rated for your engine’s weight. This is crucial for safety. Additionally, double-check the locking mechanisms to avoid any unexpected slips. Keeping your workspace organized can make a big difference as well. An untidy area can lead to misplaced tools or parts, causing unnecessary delays.

Benefits of Using an Engine Stand for Automotive Maintenance

Key Features to Consider When Choosing an Engine Stand

When choosing an engine stand, several key features should be considered. Stability is crucial. A stand that wobbles can lead to accidents. Ensure the stand has a solid base and locking wheels. Also, check the weight capacity. Different engines vary in weight, and a stand should accommodate the heaviest engines you plan to work with.

Another important aspect is adjustability. Look for stands that can easily tilt and rotate the engine. This allows for better access when working on different parts. Ease of assembly is also worth considering. Complicated setups can be frustrating and time-consuming.

Lastly, consider material quality. A stand made of sturdy steel will last longer. Plastic components can break under stress. Construction quality affects durability and safety. Small details, like bolt quality, shouldn’t be overlooked. Reflecting on these features will help you choose wisely. Make sure you evaluate your own needs carefully.

Industry Standards: Load Capacity and Stability Ratings for Engine Stands

When working on a car engine, stability is crucial. This is where an engine stand comes into play. Engine stands are designed to securely hold engines during repairs. Professional standards recommend that a good engine stand should have a load capacity of at least 1,500 pounds. This specification ensures it can handle most vehicle engines safely.

However, not all engine stands maintain stability effectively. A report from the Automotive Repair Association highlighted that up to 20% of amateur mechanics struggle with engine stand stability. Poor quality can lead to accidents or damage. It’s essential to evaluate stability ratings before purchasing. A stabilizer bar is a must-have feature for increased support. Many users overlook this detail, leading to unsafe conditions.

Load capacity is only part of the equation. An engine stand's design and material quality also impact its performance. Steel construction is preferred for durability. However, some lightweight alternatives do exist. They can be easier to move, but may compromise strength. As a result, buyers need to weigh the benefits of mobility against the need for robust support. Balancing these factors can lead to safer, more efficient engine repairs.

Recommended Practices for Safely Using an Engine Stand in Your Garage

An engine stand is essential for any serious DIY mechanic. It allows easy access to your car engine for repairs and maintenance. Using an engine stand helps minimize strain on your back and keeps the engine stable while you work.

**Tips:** Always check the weight capacity of your engine stand. Some stands can only hold lighter engines. If you're unsure, ask for advice.

When using an engine stand, ensure it’s on a level surface. A wobbling engine can lead to accidents. Wear safety gloves and goggles during your work. This simple step can prevent injuries from sharp edges or falling parts.

**Tips:** Keep your workspace organized. A clutter-free area reduces the risk of accidents. Use containers to store small parts. Label them for easier access later.